+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

About us

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

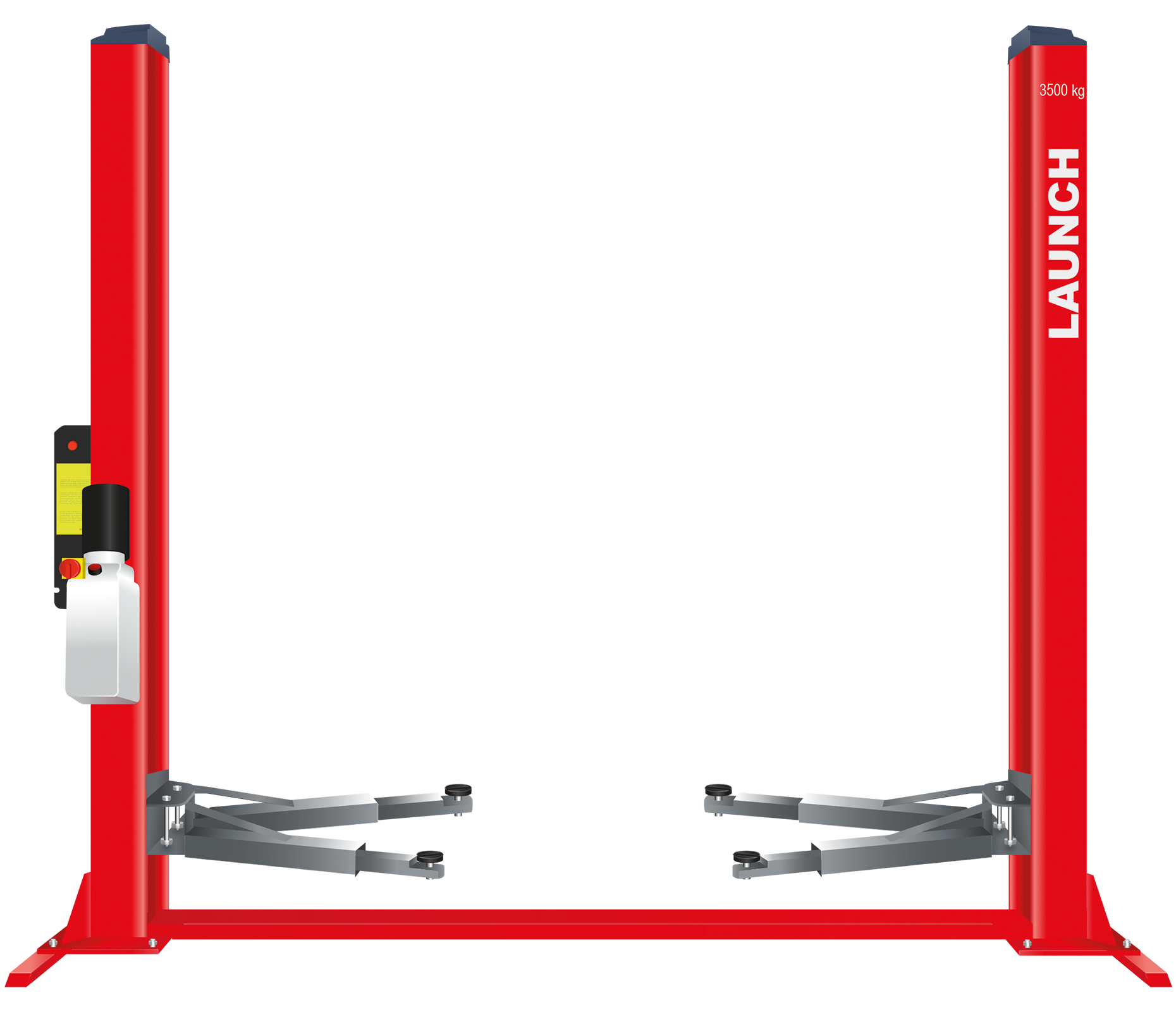

Hydraulic 2 post lift with a wide and sturdy base for installations in workshops with a low floor strength / concrete strength.

The TLT 235 SBA (E) is a solid base plate 2 post hydraulic lift. With its stable H form base, it is suitable for installation in workshops with low floor strength. With its new electrical control system and electromagnetic unlock, it can be easily operated to lift small and medium sized vehicles weighing up to 3.5 t.

Lifting Capacity

3.500 kg

Total Height

2.900 mm

Total Width

3.400 mm

Max. Lifting Height

1.920 mm

Min. Lifting Height

110 mm

Weight

735 kg

Passing Width

2.486 mm

Lifting/ Lowering Time

≤ 55s / ≤ 40s

Drive Power

2,2 kW

Voltage

380 V / 50 Hz

Concrete Strength

min. 150 mm

Oil Quantity

10 l

Support Arm Length

655 - 1.215 mm

Passing Width

2.486 mm

Concrete strength of min. 150 mm

There must be 1 metre of space between the column and the wall at the assembly site (escape route).

Assistance of an employee for unloading and setting up the columns must be provided

The electrical connection must be carried out by a qualified electrician (3PH/380V) (a test cable is brought along for testing or demonstrating the platform)

The place of installation of the lifting platform must be free when the technician arrives

Contact our distribution partners for further details or a quotation

+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH