+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

About us

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

The maintenance-free bearing of the TLT-330 A short lift platform with automatic lubrication ensures a long and efficient service life in your workshop.

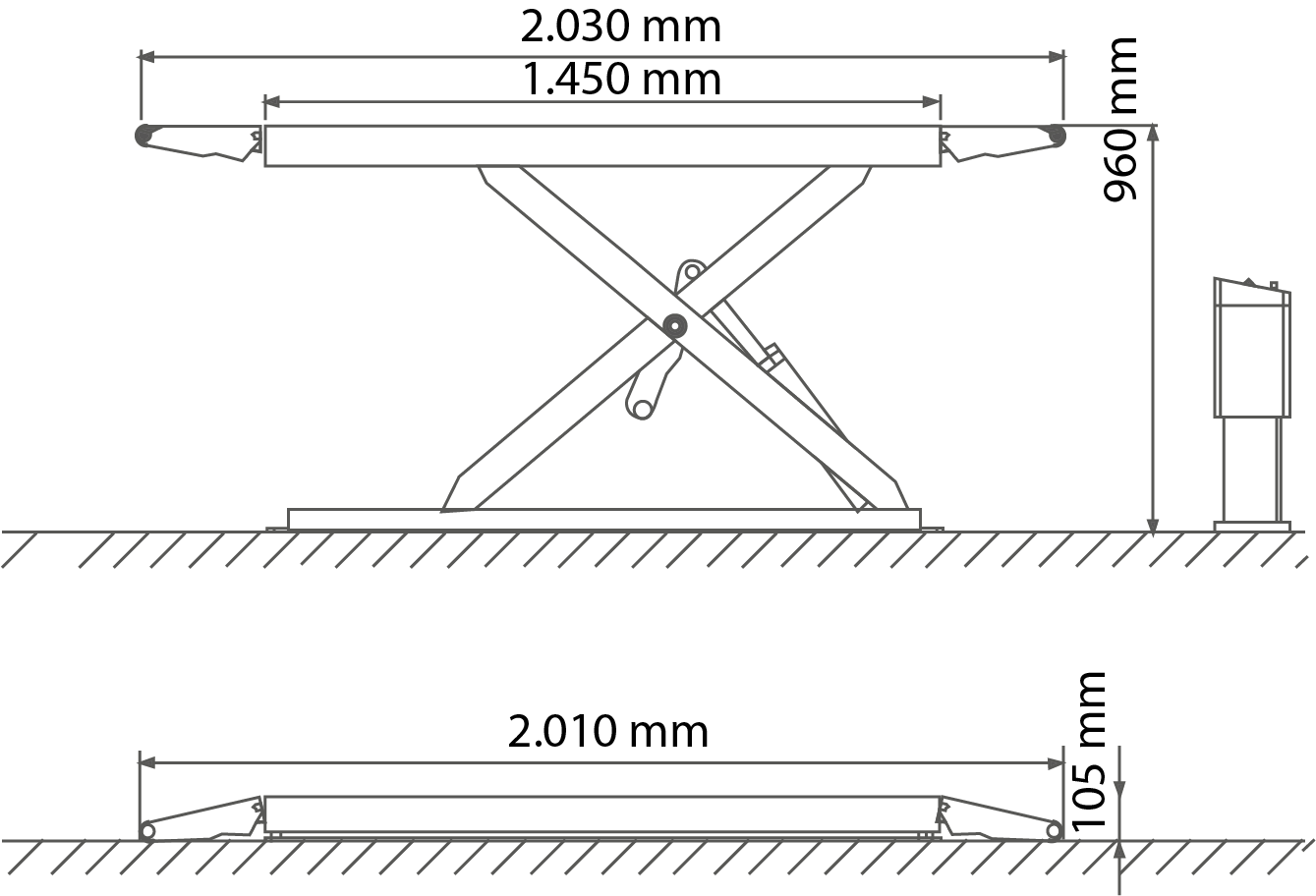

The TLT-330 A scissor lift is ideal for paint shops, tyre services or chassis work. Thanks to the compact design and the low drive-over height of 105 mm, the TLT-330 A lift is also ideal for sports cars and lowered vehicles.

Lifting Capacity

3.000 kg

Lifting Height

105 - 960 mm

Min. Lifting Height

105 mm

Runway Length / Width

1.450 / 2.030 x 530 mm

Weight

650 kg

Oil Quantity

12 l

Lifting/ Lowering Time

≤ 50s / ≤ 60s

Drive Power

2,2 kW

Voltage

380 V / 3 PH, 220 V / 1 PH

Concrete Strength

150 mm

Contact our distribution partners for further details or a quotation

+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH