+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

About us

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

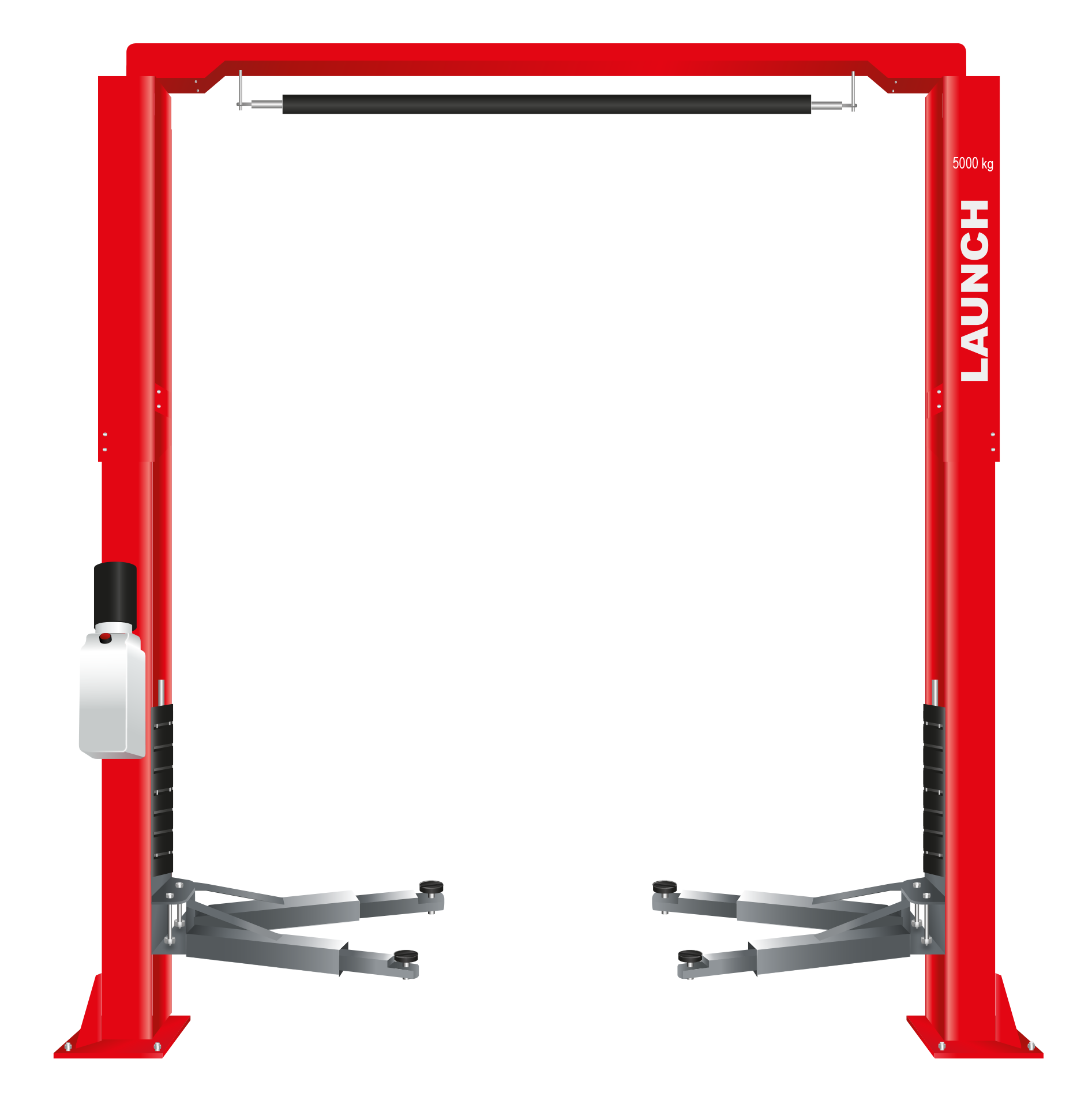

Hydraulic 2 post lift with 5 t lifting capacity. Manufactured according to international standards in compliance with the CE standard.

With a total height of 4.810 mm and 5 t lifting capacity, the LAUNCH TLT-250 AT lift is ideal for lifting various off-road vehicles, vans and many other vehicles.

Lifting Capacity

5.000 kg

Total Height

4.810 mm

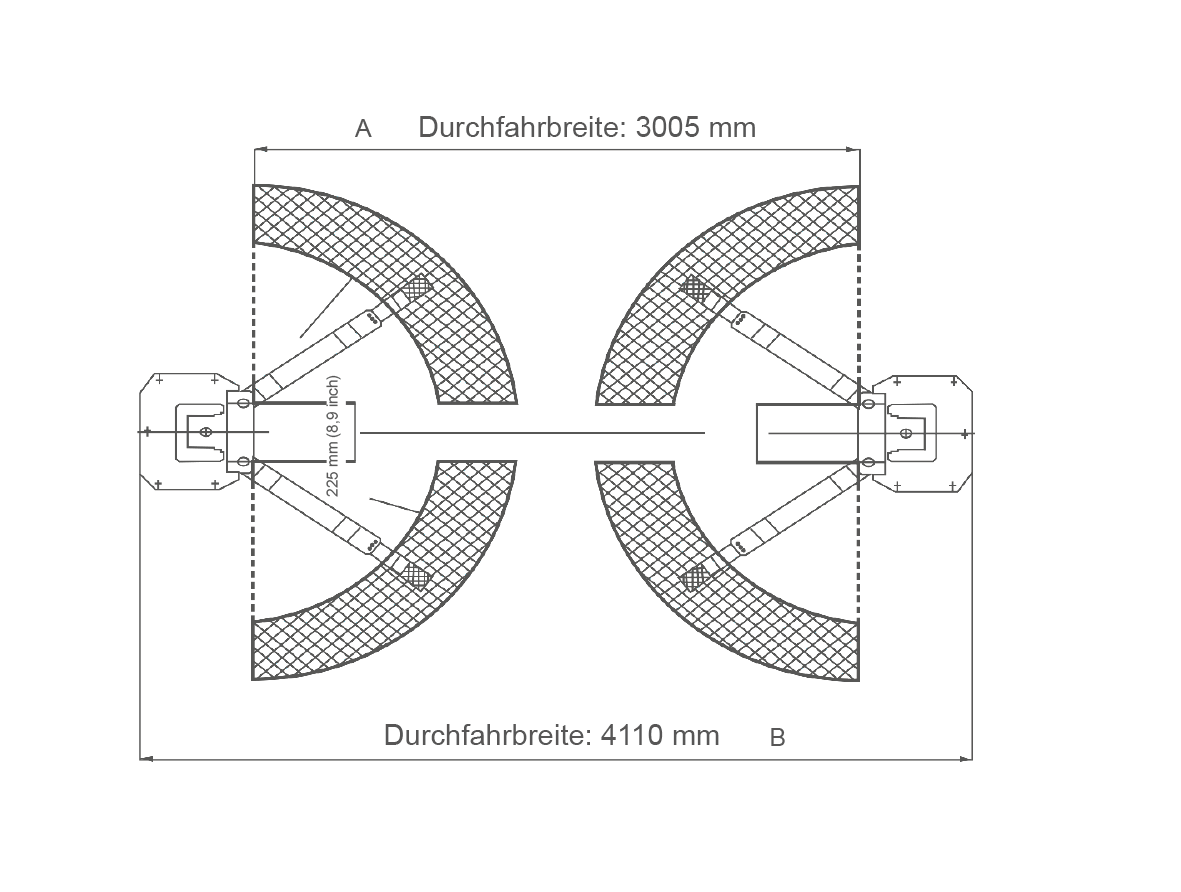

Total Width

4.110 mm

Max. Lifting Height

1.850 mm

Min. Lifting Height

110 mm

Support Arm

3-stage 950 - 1.800 mm

Passing Width

3.050 mm

Lifting/ Lowering Time

≤ 50s / ≤ 40s

Motor Power

3 kW

Voltage

380 V / 50 Hz

Min. Concrete Strength

250 mm

Oil Quantity

12 l

Weight

960 kg

Passing Width

3.050 mm

Contact our distribution partners for further details or a quotation

+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH