+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

About us

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

Hydraulic 2 post lift with rope box on the ground and 3.5 t lifting capacity. Manufactured according to international standards in compliance with the CE standard.

With an overall height of 2.860 mm and a lifting capacity of 3.5 t, the LAUNCH lift TLT-235 SBA is ideal for lifting cars up to small vans. Due to the small overall width and height, as well as the low drive-over plate, this variant of our TLT series is very space-saving and particularly popular with smaller workshops.

Lifting Capacity

3.500 kg

Total Height

2.860 mm

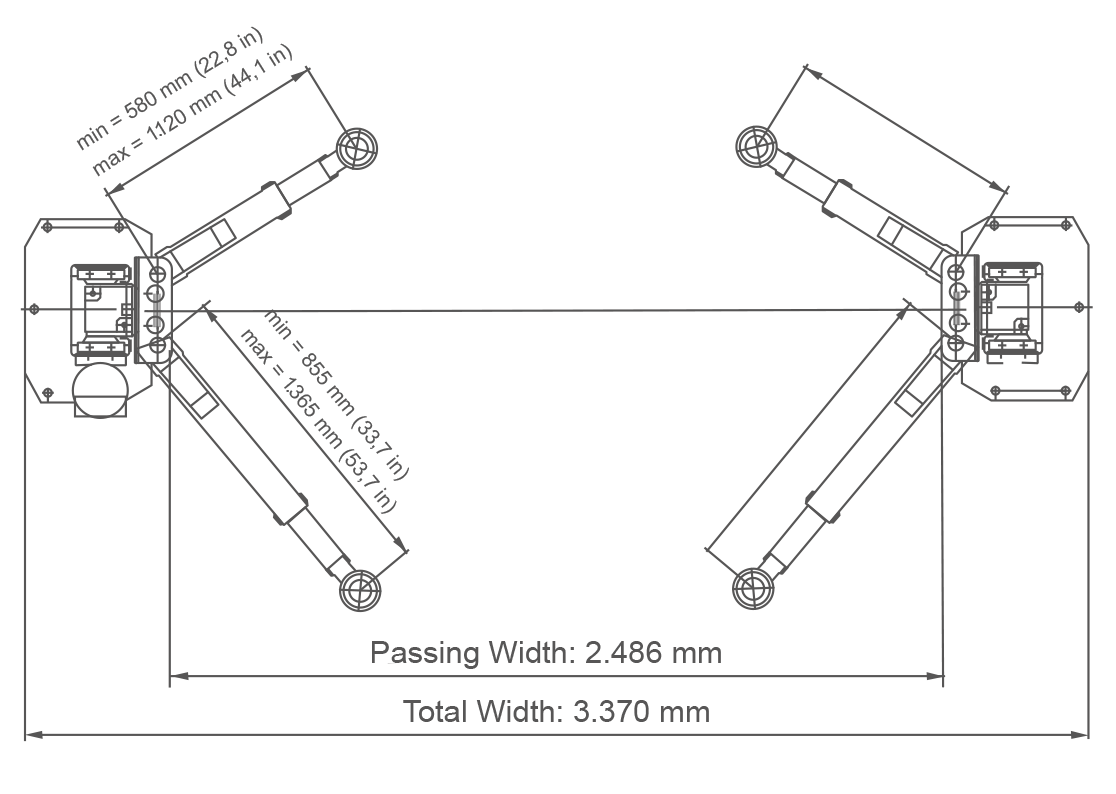

Total Width

3.370 mm

Max. Lifting Height

1.920 mm

Min. Lifting Height

110 mm

Weight

620 kg

Passing Width

2.486 mm

Lifting/ Lowering Time

≤ 55s / ≤ 40s

Motor Power

2,2 kW

Voltage

380 V / 50 Hz

Concrete Strength

250 mm

Oil Quantity

10 l

Support Arm

2-stage 855 - 1.365 mm

3-stage 580 - 1.120 mm

Support Arm

2-stage

855 - 1.365 mm

3-stage

580 - 1.120 mm

Support Arm (optional)

2-stage 800 - 1.200 mm

2-stage 980 - 1.570 mm

Support Arm (optional)

2-stage

800 - 1.200 mm

2-stage

980 - 1.570 mm

Lifting/ Lowering Time

≤ 55s / ≤ 40s

Motor Power

2,2 kW

Voltage

380 V / 50 Hz

Concrete Strength

250 mm

Oil Quantity

10 l

Passing Width

2.486 mm

Support Arm (optional)

2-stage

800 - 1.200 mm

2-stage

980 - 1.570 mm

Support Arm

2-stage

855 - 1.365 mm

3-stage

580 - 1.120 mm

Concrete Strength of 250 mm or more

There must be 1 metre of space between the column and the wall at the assembly site (escape route).

Assistance of an employee for unloading and setting up the columns must be provided

The electrical connection must be carried out by a qualified electrician (3PH/380V) (a test cable is brought along for testing or demonstrating the platform)

The place of installation of the lifting platform must be free when the technician arrives

Contact our distribution partners for further details or a quotation

+49 (0) 2273-9875-0

info@launch-europe.de

Heinrich-Hertz-Str. 10

D-50170 Kerpen

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH

© 2020 All Rights Reserved | LAUNCH Europe GmbH